Key takeaways:

- Firms can reach the next level of operational performance by adapting digital supply chain management

- Major characteristics of Supply Chain 4.0 are customer centricity, automation, transparency, and flexibility

- Industry 4.0 can optimise SCM in the planning stage, logistics, as well as vendor management

- SCM 4.0 can optimise inventory management and thus make things easier for the customers

- SCM 4.0 can have a positive impact on global value chains by improving productivity

- The digital supply chain can help derive critical insights for organisations

- SCM 4.0 is likely to grow globally and have a higher presence in the upcoming years

Industry 4.0 is a buzzword in today’s world. It has impacted every industry, and Logistics and Supply Chain Management has not been a deviation from the norm. Smart Supply Chain Management or Supply Chain 4.0 refers to the management Industry 4.0 causes upheaval and forces organisations to reconsider how they plan their supply chains. Several new technologies have arisen that are changing conventional workplace practices.

Megatrends and changing client expectations are other factors. Along with the requirement to adapt, supply chains also have the chance to utilise newly developing digital supply chain business models, reach the next level of operational performance, and change the organisation by implementing digitisation in supply chain management.

What is Supply Chain Manangement 4.0?

Supply chain management is significantly impacted by many megatrends, such as the continued global expansion of rural areas and the distribution of wealth to previously under-served areas. Another such trend is SCM 4.0. Below are a few characteristics of SCM 4.0:

- Focus on the customer: There is a significant focus on customer-centric design, production, and sales of unique items using an omnichannel strategy and cutting-edge manufacturing techniques like additive manufacturing.

- Interconnected platforms: Through platforms in a network of businesses, customers, suppliers, and partners (such as logistics service providers) interact and operate simultaneously in real-time based on shared and standardised data.

- Automation: The primary objective is to boost productivity by using robotics to flexibly automate physical and repetitive tasks.

- Transparency: GPS and CPS offer improved visibility into the various supply chain factors (such as bottlenecks, delays, and product traceability) (eg: location of materials, proof of provenance etc).

- Proactiveness: Based on real-time data analytics, machine learning, and AI, decision-makers respond anticipatorily to changing situations and unforeseen occurrences.

Thus, if SCM 4.0 is adopted wisely, there is a significant role for IT in supply chain management.

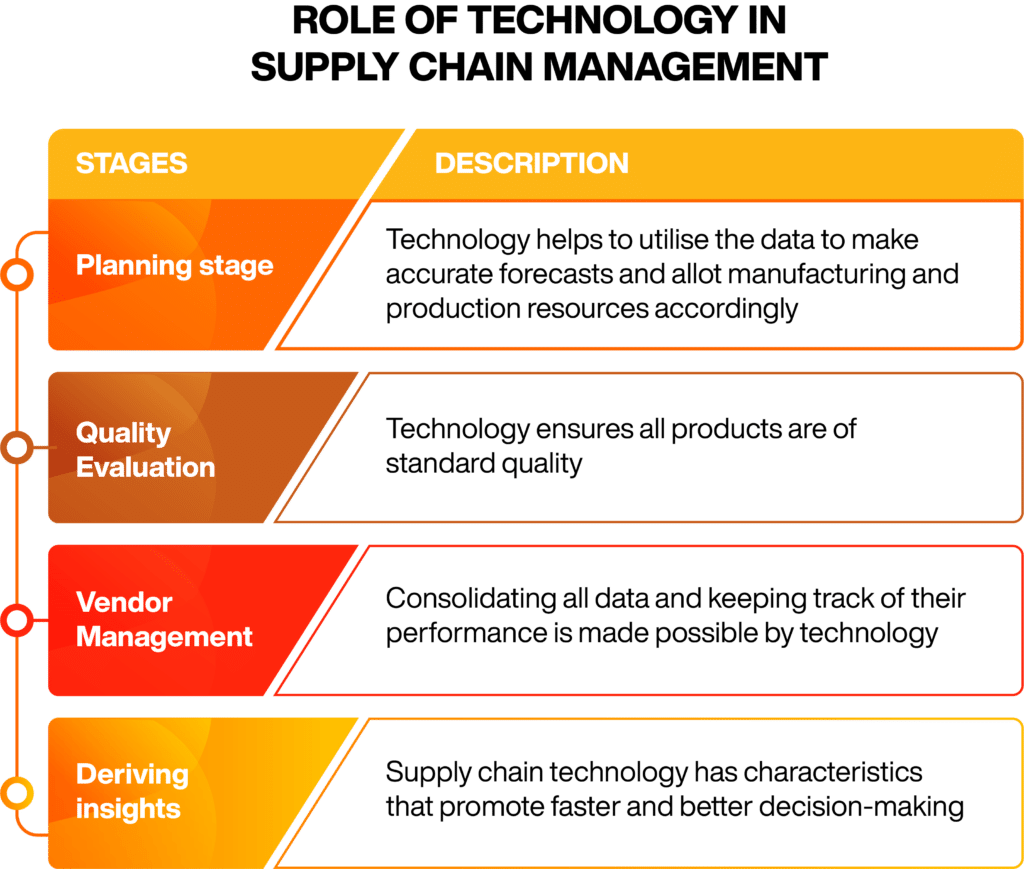

The role of technology in Supply Chain Management

Data within the supply chains has been ever-growing. The data gathered from various functions of supply chain management are not present in an integrated manner. If the information is not consolidated, it becomes pretty tricky for organisations to analyse the data and derive insights from it. Be it the planning stage or logistics, the role of IT in supply chain management is immense. Below are a few ways technology impacts supply chain management –

- Planning stage: Without a doubt, the planning stage requires significant data. Structured information and the minutest details are necessary to predict and ensure smooth operations. Modern technology has further altered the manufacturing and production process. When it comes to the chemical and paint industries, in particular, technology can understand the product’s composition and qualities and automatically choose the best way to produce it per the client’s needs. For instance, the German paint manufacturer BASF recently adopted machine learning technology to interpret customer needs and guide manufacturing units. The aim was to provide the clients with their desired paint compositions.

- Quality Evaluation: Another area where technology has benefited several sectors is quality evaluation. To evaluate the quality of seeds, agricultural seed manufacturers take advantage of a range of cameras in real-time. Such information is gathered, organised, and interpreted to provide compliance reports that may be of additional assistance. Companies with best-in-class supply chains can see orders, inventory, workforces, transportation networks, warehouses, and partner activity. They put that information to use by predicting events more clearly, making better plans, and responding more quickly. A business will react quickly to unplanned, possibly disruptive occurrences if it has complete and understandable supply chain information. Thus, there is a significant role of IT in supply chain management and quality evaluation.

- Vendor management: In addition to the planning stage, vendor or third-party management heavily relies on analytics. Vendor partners are involved in the supply chain at every point and work closely with it to ensure its success. Consolidating all data and keeping track of their performance is made possible by data, technology, and eventually analytics, which is useful when it comes time to renew contracts. For instance, it is essential to continuously track metrics such as trips completed, rates supplied (compared to market prices), their order acceptance rates, OTIF (on-time, in-full) delivery score, driver performance, etc., if a firm works with several transportation contractors.

- Deriving insights: Insight is the cornerstone of crucial decision-making. It is simpler to review data, get insights (on issues like consumer demand, storage/transportation constraints, and supplier lead times), and make choices that have both direct and indirect implications on the functioning of the supply chain as a whole due to supply chain technology. In addition, supply chain technology has characteristics that promote faster and better decision-making. It enables companies to process data and run simulations in real-time depending on numerous circumstances, allowing them to weigh potential options. By comprehending the tradeoffs involved with each scenario response, effective decisions can be taken.

Impacts of supply chain 4.0 from the lens of a customer

An in-store retail outlet is the last stage in a conventional consumer supply chain. When items are out of stock, either because they are normally on the shelf but are not when the customer visits the store or because they are items the customer wants to buy but the business does not carry, it commonly frustrates the customer. The solutions in these situations are well known.

The customer might want to speak to the manager, or the salesperson would go to the godown to check for the item. By this point, the customer may have given up and moved on to a rival or avoided making the transaction altogether.

Applications of IoT are increasingly being utilised to support “customer-managed inventory” (CMI) and “vendor-managed inventory” (VMI) management techniques. The “just-in-time” manufacturing revolution that Toyota and other corporations helped pioneer in the 1960s is equivalent to the supply chain management transformation brought about by these tactics. In such models, data is first supplied by a client, for instance, by scanning a barcode connected to a purchase, and is subsequently sent up the supply chain to the warehouse/distribution centre.

The information is then transmitted to the distribution centre so that orders may be fulfilled using technologies like RFID tags. Electronic Data Interchange (EDI) mediates the information in question. Since it is still difficult to predict demand accurately, inventory management models like scan-based trading or consignment share the risk between suppliers and retailers by allowing retailers to physically possess inventory while suppliers retain ownership. This way, the sale between the supplier and retailer does not occur until the final customer checks out at the register. There may be more intricate variations of this transaction.

EDI-driven CMI reduces forecasting mistakes along the supply chain by mediating several links between retailers, warehouses, manufacturers, and suppliers of inputs to production. All-in-all, it can help in future supply chain tracking and forecasting.

Impact of supply chain 4.0 on global value chain

Supply Chain 4.0 may be viewed as a collection of technologies that are more likely to be implemented due to advanced management practices, or it can be considered an advanced management practice. Recent survey-based research has demonstrated that better management techniques, such as those connected to the adoption of Supply Chain 4.0, are likely to increase productivity and profitability and result in higher-quality outputs made using higher-quality inputs.

Supply Chain 4.0 aims to improve critical management skills such as efficient target creation, data gathering and analysis to track progress toward these goals, inventory management, coordination of targets/progress across production stages, and worker supervision and incentives.

By reshoring typical labour-intensive operations from developing nations back to developed countries, Supply Chain 4.0 technology may help businesses reduce the number of steps in supply chains. By lowering the amount of labour needed, these technologies increase the profitability of some production stages carried out in high-wage countries.

Thus, it decreases the incentive for businesses to locate there and the significance of low labour costs in determining comparative advantage and favouring the integration of various production stages at a single automated location. There could be a significant drop in monitoring tracking costs which would lower the overall costs. Supply Chain 4.0 methods are expected to be adopted and disseminated to varying degrees across businesses and nations.

Therefore, in the near term, it may lead to increasing industrial concentration in sectors where it is significant and income disparity between nations. Nations with better internet, companies with higher levels of digital entrepreneurialism, and businesses that have mastered earlier generations of supply chain management techniques are likely to benefit from using Supply Chain 4.0 techniques.

ALSO READ: Supply Chain Management and Operations Management go hand in hand

Benefits of Industry 4.0 on SCM

Below are two primary benefits of the integration of Industry 4.0 with SCM-

- Deriving critical insights: Insight is the cornerstone of crucial decision-making. It is simpler to review data, get insights (on issues like consumer demand, storage/transportation constraints, and supplier lead times), and make choices that have both direct and indirect implications on the functioning of the supply chain as a whole due to the supply chain technology. In addition, supply chain technology has characteristics that promote faster and better decision-making. It enables companies to process data and run simulations in real-time depending on numerous circumstances, enabling them to weigh potential options. Better judgments may be made by comprehending the tradeoffs involved with each scenario response. Thus, Industry 4.0 can have a significant impact on various functions of supply chain management.

- Flexibility and agility: Agility is improved through technology in the supply chain. With improved access to information and simulations, executives may solve issues or develop new business opportunities faster when they have a superior understanding. You won’t be able to operate quickly if your organisation, procedures, or systems have barriers or silos. You must monitor occurrences throughout the whole supply chain, assess their effects, and develop preventative measures. Optimised supply chain technologies will suggest the best actions, which you may change as soon as such actions become accessible. This skill is essential in the fast-paced corporate environment of today.

Wrapping up

Supply chain 4.0 is the most technologically sophisticated version of the supply chain, allowing businesses to overcome various obstacles that the sector faces. Many industrial businesses are already making use of the distinctive qualities that supply chain 4.0 has introduced. In the upcoming years, over 80% of firms are expected to invest in linked technology, according to Gartner. Having said that, it appears to be a good opportunity to invest in this distinctive technology ecosystem and develop resilience for the future. To fully profit from these ground-breaking technologies, working in partnership with a reputable technology partner is integral.

A postgraduate certification programme in Logistics & Supply Chain Management offered by the Manipal Academy of Higher Education (MAHE) through Online Manipal can serve as the perfect course for individuals aspiring to build their careers in digital supply chain management. Online Manipal has curated a programme to help such individuals take leverage of the growth of SCM 4.0. Visit Online Manipal to know more about the PGCP programme.

Prepare for your next career milestone with us